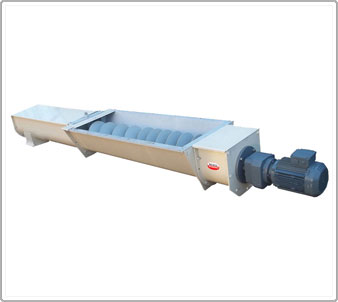

SECREW CONVEYER

SCOPE OF SCREW CONVEYER

It is used to convey the granular and grinded products horizontally for collecting, distributing, mixing and tempering processes. It is designed to satisfy the most rigorous sanitation requirements. It can be applied for high-precision volumetric proportioning or for feeding material at a controlled rate to a gravimetric system. In addition, this screw feeder can be used for conveying powdered products inthe food industry. Its throughput capacity is as high as 170 m3/h.

APPLICATIONS OF SCREW CONVEYER

| At food industry. |

| Flour and semolina mills. |

| Feed mills. |

| At Cement industry. |

|

| At chemical industry. |

| At wood processing industry. |

| At lime processing industry. |

| At salt processing industry. |

| For other similar industries. |

|

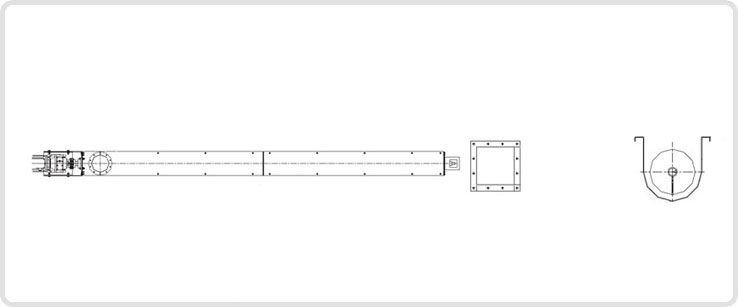

STRUCTURE OF SCREW CONVEYER

| 1. |

Semi –cylindrical troughs and out-wall installed ball bearings. |

| 2. |

Plastic bushing installed intermediate bearings allows free maintenance Spiral The screws or spirals are welded on a pivot in a regular pitch Types of drive. |

| 3. |

Motor with coupling. |

| 4. |

Flanged motor with coupling. |

| 5. |

Chain driven type motor Special designs (at request). |

| 6. |

Stainless steel construction. |

| 7. |

Variable screw pitches. |

| 8. |

Special painting applications. |

| 9. |

With feeding box The modular system allows it to be used for many and variable applications. |

|

ADVANTAGES OF SCREW CONVEYER

| 1. |

High quality. |

| 2. |

High efficiency. |

| 3. |

High extraction. |

| 4. |

High capacity. |

| 5. |

Long life. |

| 6. |

Maximum hygiene. |

| 7. |

Maximum security. |

| 8. |

Maximum simplified using. |

| 9. |

Low periodical maintenance. |

| 10. |

Low delay to change the spares parts. |

| 11. |

Low energy consumption. |

| 12. |

Noiseless. |

| 13. |

Perfection and aesthetic. |

|

FEATURES & ADVANTAGES OF SCREW CONVEYER

| 1. |

Standardised dimensions and modular sections |

| 2. |

Standardised spare parts |

| 3. |

Supply and manufacturing possibility for special requests and applications |

|