Hammer Mill

- Home

- Hammer Mill

- Grinding Section

Hammer Mill

SCOPE OF Hammer Mill

Hammer Mill / Pulverizer is a machine designed for preliminary size reduction in fine grinding of soft to medium-hard materials. Material of close density granulation can be pre compounded and ground. It is found more economical for general all round work. Basic grinding unit is built for continuous production depending on necessity.

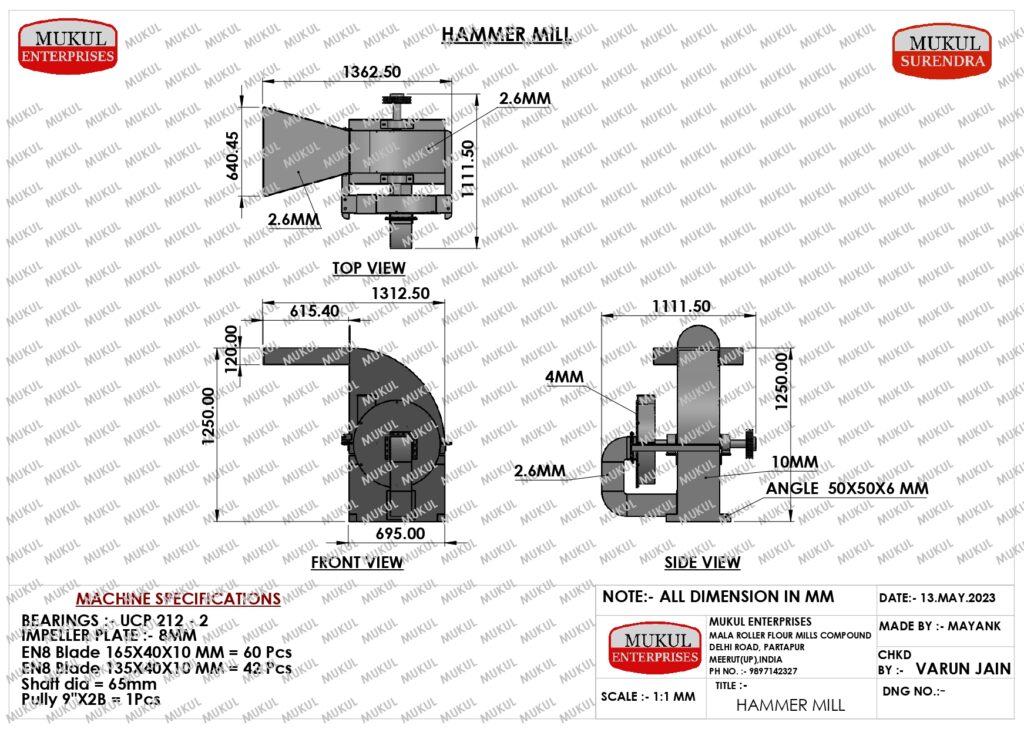

Technical Specifications

| MODEL | CAPACITY (Kg/Hrs.) |

LENGTH (mm) |

WIDTH (mm) |

HEIGHT (mm) |

|---|---|---|---|---|

| HM7510 | 75-100 | 800 | 700 | 900 |

| HM2050 | 200-500 | 900 | 800 | 950 |

| HM3050 | 300-500 | 1000 | 900 | 1050 |

| HM5070 | 500-700 | 1240 | 1070 | 1140 |

Count on the Best Hammer Mill Machine Manufacturer: Mukul Enterprises

Count on the Best Hammer Mill Machine Manufacturer: Mukul Enterprises The drum sieve machine is a type of equipment that is used in industries, especially food processing industries, to separate different particles based on their sizes by vibrating. In food grading, a drum sieve machine is employed to sort out the unwanted materials and objects from the food grains depending on their size. This industrial sieving equipment includes rotating cylindrical drums equipped with two brands of screens: square hole screens and slotted or long hole screens. The grain is sorted and purified due to the drum movement and sieves, where the materials that are to be processed pass through the sieves while larger impurities are separated.

This is a mill with several hammers placed on the central shaft that is used for grinding and pulverising materials by repeatedly striking them. These are attached to the rotor and move at high speed, crushing the feed material against a breaker plate. This process can also be controlled by altering the size of the screens, thus producing different products in the end. The hammer mill machines by Mukul Enterprises are used in the food industries, chemicals, pharmaceuticals, cosmetics and minerals, processing and waste management industries for milling processes.

The key benefits of using a hammer mill machine by Mukul Enterprises include the following:

➤ Fine grinding with fairly constant particle size distribution.

➤ The process of size reduction is energy efficient, and the amount of heat produced is low.

➤ The machine is easy to maintain and clean.

➤ Subject to application, different finishes can be provided.

➤The construction is strong and sturdy enough to withstand the weight and force that come with heavy materials.

Mukul Enterprises is the leading hammer mill machine manufacturer in India. We have been in business for almost 50 years and are a worldwide manufacturer of efficient size-reduction equipment. Established in 1975, our company began with a location area of 100m sq. and three employees. We are currently running a 10,000 sq. m. production house with more than 150 employees. We provide a full spectrum of size reduction systems and equipment, such as hammer mills. We also offer pre packaged services for the establishment of flour and feed mills in various parts of the world. We seek to maintain a steady pursuit of R&D to advance effective technologies. Our company has an annual turnover of approximately $50 million every financial year.

For anybody interested in an industrial hammer mill machine, it may be worth considering the products offered by Mukul Enterprises, which stocks the latest models at reasonable prices. Our skilled technicians can also guide you in selecting the appropriate hammer mill machine relevant to your processing needs.