Impact Detacher

- Home

- Impact Detacher

- Milling Section

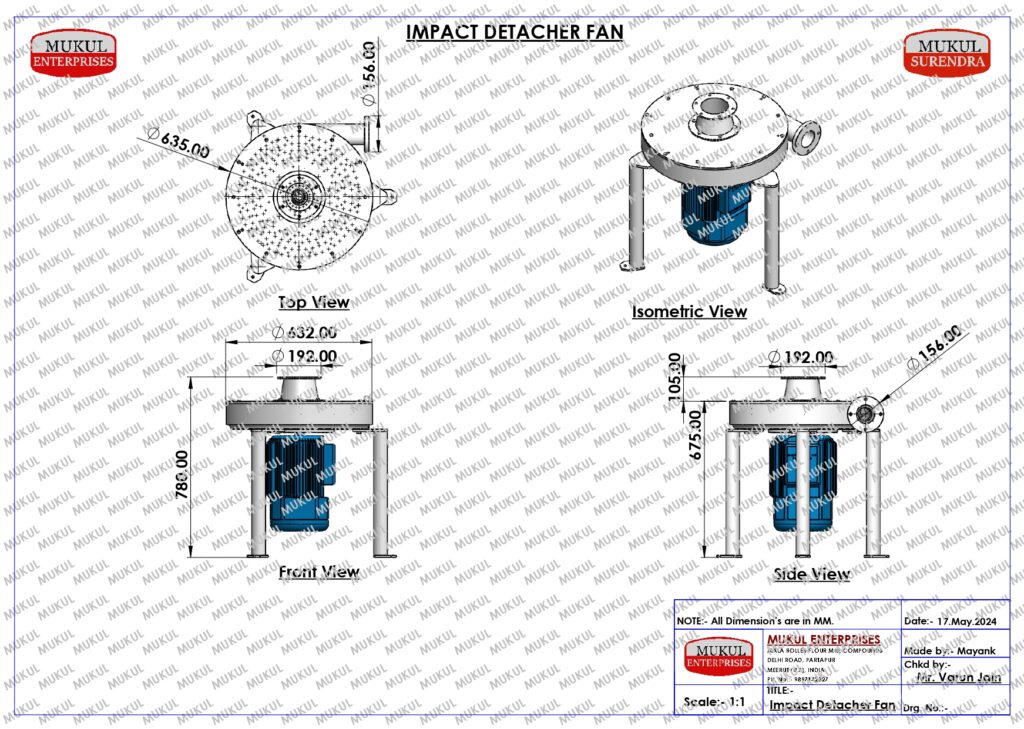

Impact Detacher

SCOPE OF IMPACT DETACHER

It is used to realize separating and grind process at the semolina passages in the flour diagrams, this process increases the yield of flour and consumes less energy comparing to other grinders.

| APPLICATIONS OF IMPACT DETACHER |

|---|

| At Food Industry |

| At the coarse and fine semolina passages in the flour and semolina mills |

| Just after roller mills or at the peak point of pneumatic tubes to be used as a right-angled elbow |

| At other similar industrial plants |

The product is fed through the center of the machine. Uniform and smooth distribution of product is provided by means of radial wings of the rotating disc. High rotation speed creates a gradually increasing centrifugal force, which throws the product towards the fixed disc's pins. The impact force depends on the structure of pins. The broken but not ground parts, which come from the passages and stuck on fine and medium size semolina are loosened and separated from each other. Because of free grinding the hard and soft semolina grains are affected differently. Therefore, it causes an automatic grinding between different sized parts. The parts, which are of equal size, are grind by homogeneous breaking quality. So that high flour yield is obtained. The rate of ash almost stays stable or increases slightly which can be neglected. As a result with the high productivity the obtained high flour yield will provide for a shortened flour diagram. The large particles and foreign materials are prevented from getting into the machine by installing a sieve at the inlet of the detacher.

| S.No | Content |

|---|---|

| 1 | Durability and long lifetime comparing to other impact detachers |

| 2 | Installation possibilities, on the floor or to be suspended from the ceiling |

| 3 | Minimum and easy maintenance |

| 4 | Low energy consumption and high efficiency |

| 5 | Hygienic working conditions |

| 6 | Possibility of shortening of flour diagram |

| 7 | Easy installation and less space need |

| 8 | Low investment and operational costs |