INTENSIVE DAMPENER

SCOPE OF INTENSIVE DAMPENER

The Intensive Dampener is a machine that has a broad range of applications. It is used in the grain processing plants to moisten the grain at a desired rate. The dampener is used in wheat milling for wheat kernels, flour and bran: It is employed for the dampening of grain, mixing flours or for moisture addition in flours and brans. Mukul Enterprises recommends the use of intensive dampener in grain processing units that face problem of electricity.

APPLICATIONS OF INTENSIVE DAMPENER

| At the cleaning units of the flour and semolina mills |

| At the grain processing plants where moistening process is required |

| At areas where quality of grains is low |

|

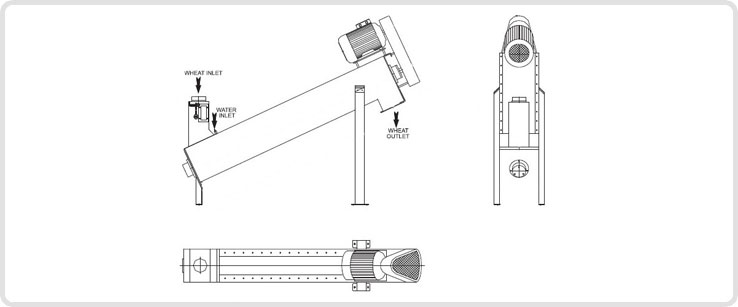

STRUCTURE OF INTENSIVE DAMPENER

| 1. |

The machine is constructed of stainless steel, consisting of semi circular 25° inclined worm with cover. |

| 2. |

Rotor consisting of 600 mm screw and 1700 mm of variable pitch mixing paddles. |

| 3. |

Square section iron structure supporting the screw conveyor, water flow control equipment and motor. |

| 4. |

Manually operated valve for closing water circuit. |

|

WORKING PRINCIPLE OF INTENSIVE DAMPENER

The grain flow entering the casing signals the water flow sensor; the water is sprayed into the grain and mixing begins. The blades convey the grain mixed with water to the grain outlet. The intensive dampener is capable of adding up to 5% water to cleaned wheat with even distribution of moisture. The two-component injection system and the high material whirling via special rotor result in optimal intermixing with the atomized liquid, thus ensuring efficient moisture addition in flour and bran. This avoids grains breakage, minimizes the wear of rotor and prevents unbalancing. The water distribution to kernel is fast and uniform with thorough penetration and absorption.

FEATURES & ADVANTAGES OF INTENSIVE DAMPENER

| 1. |

High moistening ratio. |

| 2. |

Low energy consumption. |

| 3. |

Durability and long lifetime. |

| 4. |

Minimum and easy maintenance. |

| 5. |

Easy and quick installation. |

| 6. |

Low investment, maintenance and operational cost. |

| 7. |

Automatic flow rate control and adjustable moisture rate Stainless steel construction. |

|