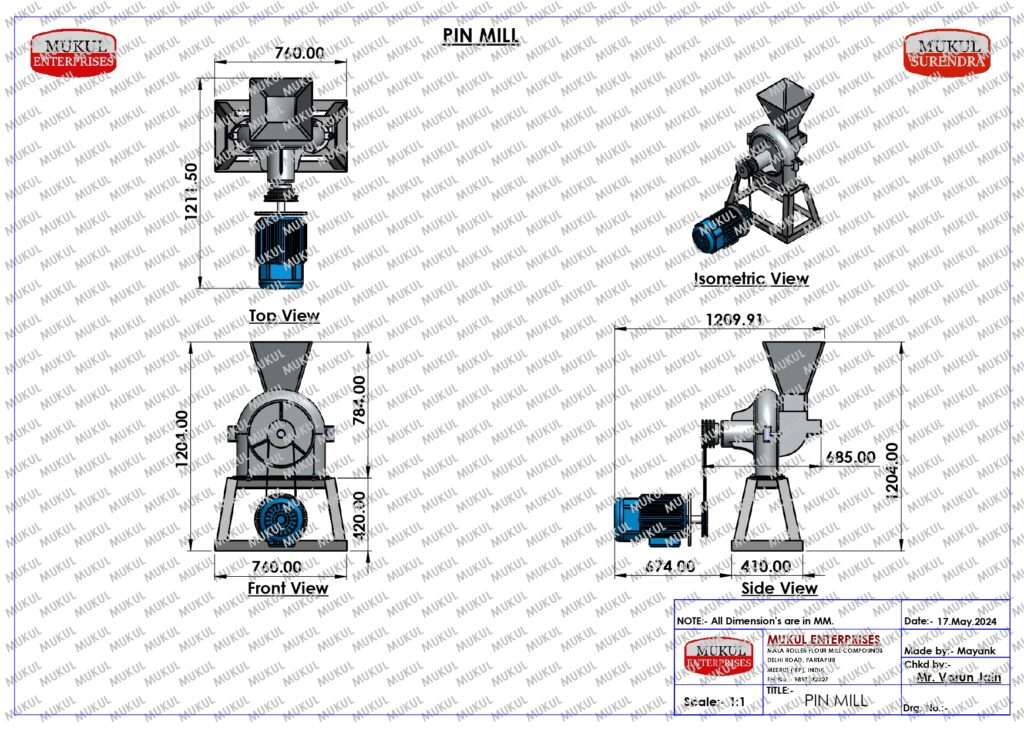

Pin Mill

- Home

- Pin Mill

- GRINDING SECTION

Pin Mill

SCOPE OF PIN MILL

Pin Mill is a machine that, homogenizes substances through repeated impact. It is a type of vertical shaft impactor mill and consists of two rotating disks with pins embedded on one face. The disks are arrayed parallel to each other so that the pins of one disk face those of the other. The substance to be homogenized is fed into the space between the disks and either one or both disks are rotated at high speeds.

| APPLICATIONS OF PIN MILL |

|---|

| Flour, semolina, rice mills |

| Porridge Plant |

| Corn, Soya, Pea, cocoa, coffee plant |

| Pharmaceuticals |

| Sugar, Salt, Spice Plant |

| Dairy Plants |

| Dehydrated vegetable processing |

| At other similar industrial plants. |

| S.No | Content |

|---|---|

| 1 | Pin Mill can be manufactured to a number of standards, from the basic machine in all mild steel up to dairy standard with all parts in stainless steel allowing it to be washed down. |

| 2 | The machine can be gravity fed or installed in pneumatic conveying lined which allows it to be adapted to suit many applications. |

| 3 | It’s milling zone is consist of rotary pins and static pins. Particles hit these pins and get split. Particles can get abundant times of hit because there are several rows of pins. |

| 4 | The rotary pins can suck airs to reduce the heat generated by friction. There is a air sealing device to protect bearing keep clean. |

The grinding action within the Pin Mill is achieved by impacting the product particles with a series of hardened steel pins. The material to be ground is pneumatically or mechanically conveyed from the hopper to a Pin Rotor where the break-up of the material occurs. The product enters through the eye of the machine and then passes through rows of pins rotating at high speed between stationary pins. The product particles are shattered into fragments as they progress towards the outlet. This action creates a fan effect and a high volume of air is drawn through with the product, keeping it cool. The machine's grinding action can be controlled by altering the feed rate to the machine and the speed of the rotor. Mukul Enterprises also offers a size reduction system complete with cyclones, dust collectors, fans and discharge valves.

| S.No | Content |

|---|---|

| 1 | Low energy consumption, high capacity and operating efficiency. |

| 2 | Easy and minimum maintenance, hassle free operation. |

| 3 | The pin mill cover is hinged which means all of the components in contact with the grinding material can be easily accessed and cleaned. |

| 4 | Durability and long lifetime |

| 5 | The whole pin mill assembly can be vertically extracted for maintenance or any needed repair work. |

| 6 | Noiseless working |