C.I. Roller Mill (1000 m.m x 250)

- Home

- C.I. Roller Mill (1000 m.m x 250)

- Grinding Section

C.I. Roller Mill (1000 m.m x 250 )

SCOPE OF C.I. Roller Mill (250 x 1000 m.m.)

The roller mill is used in order to break and crush the wheat. The most important machine of a flour mill, it consists of two pairs of parallel working rolls. The product that collects into the inlet glass moves the pneumatic pressure plates and the feed rolls start to feed the products homogenously into the rolls. In the meantime, the gap between the rolls is reduced by pneumatic pistons and the product is grinded by passing between the rolls.

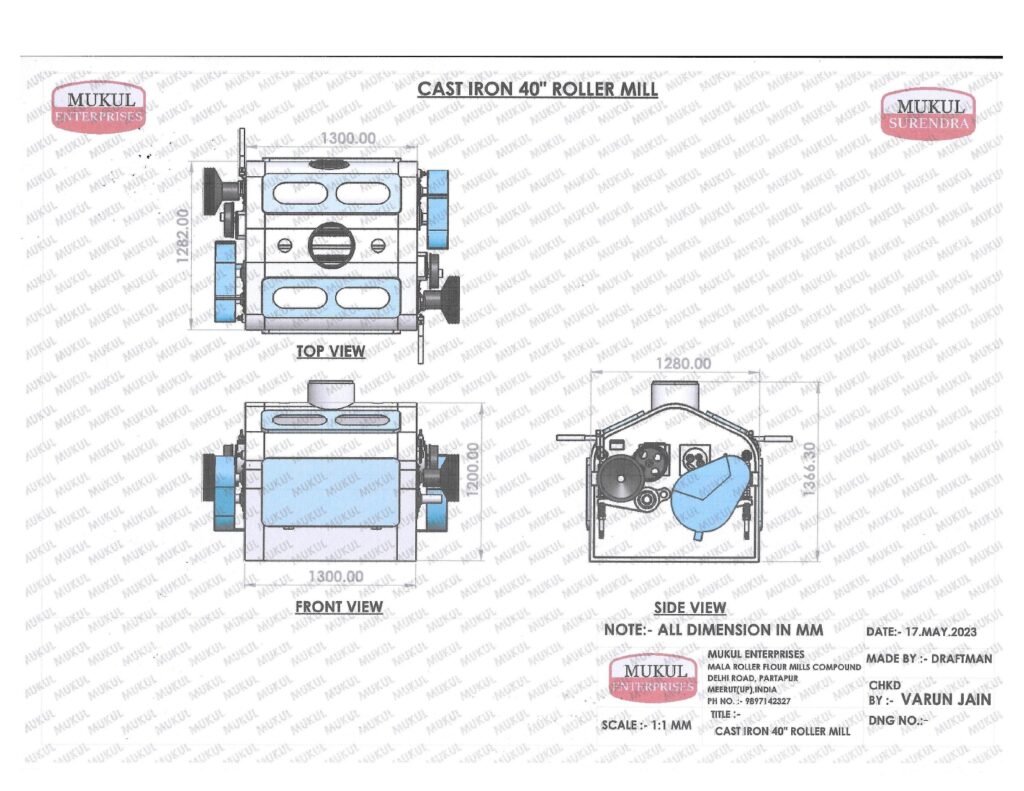

Technical Specifications

| MODEL | CAPACITY (MT/Hrs.) |

LENGTH (mm) |

WIDTH (mm) |

HEIGHT (mm) |

|---|---|---|---|---|

| CIRM | 1820 | 1760 | 1710 |

Mukul Enterprises: The Leading Rolling Mill Machine Manufacturer in India

The demand for rolling mills has enhanced the growth of rolling mill manufacturers in India, and Mukul Enterprises has emerged as the best rolling mill machine manufacturer in the country. Our services mainly involve consulting and contracting services for rolling mill plants, with a focus on producing high-quality, efficient and productive plants.

We have fully equipped manufacturing facilities to provide the best quality rolling mill machines for flat rolling, section/profile rolling, wire rod mills, etc. We have provided hundreds of rolling mill plants in India as well as overseas.

The rolling mill machines that we manufacture are built to high-tech standards with fine engineering that ensures smooth working, low incidences of breakdown, easy control and operation and relatively low service requirements. This means that we only employ very high grade materials obtained from accredited manufacturers to construct strong and durable machines.

Not only do we design and manufacture the plant layout for easy operation, but we also offer installation services and follow-up. It is made easy for you with the help of our highly professional staff, who takes care of all the inconveniences so that you can concentrate on what really matters to your business.

The rolling mill plants that are produced by Mukul Enterprises are made of modern plant and equipment, including the roller mill machine, which is considered to be very crucial. The roller mill machine comprises two pairs of active steel rolls that rotate in opposite directions to crack and grind wheat grains that flow through the inlet slide. Next, the soft wheat particles are crushed and ground to a fine powder that will be processed further. Being a leading roller mill machine manufacturer, Mukul Enterprises provides roller mills of different sizes based on the needs of its clients.

Starting from the conventional, prefabricated, small pod-like structure of approximately 100 sq. Mukul Enterprises began as a small establishment with three employees. Today, the company possesses a giant industrial-scale modern factory with 10,000 sq. m. and more than 150 well-trained and experienced personnel in the design, manufacturing, installation and commissioning of turnkey rolling mill plants. The adequate action and ideas of the founders and employees have made us a reputed rolling mill machine manufacturing organisation not only in India but in the worldwide market.

With the expansion programmes on the line, Mukul Enterprises is ready to strengthen its hold in the rolling mill machine manufacturing industry further.