Vibro Separator

- Home

- Vibro Separator

- Cleaning Section

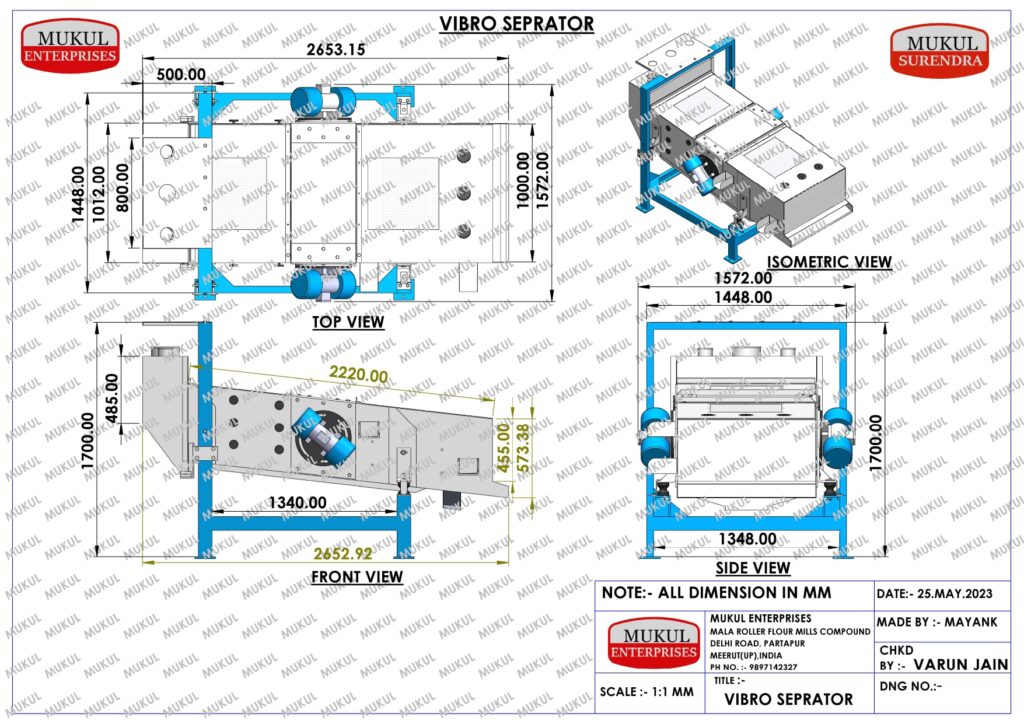

Vibro Separator

SCOPE OF VIBRO SEPARATOR

Separator is a machine used primarily for grain cleaning in the milling of wheat, durum wheat, corn (maize), rye, soybeans, oats, buckwheat, spelt, millet and rice as well as in storage elevators. It separates coarse and fine impurities from grain via screening and classifies a broad range of materials according to size. In addition to its main field of application, Separator is also employed successfully in feed mills, seed cleaning plants, oilseed cleaning and cocoa bean grading plants.

| APPLICATIONS OF SEPARATOR |

|---|

| Flour and Semolina Mills |

| Seed cleaning plants, |

| Cereals cleaning and calibration centers |

| Malt factories |

| Feed mills |

| Cereal storage silos |

S.NoContent

| 1. | Vibrating structure supported by elastic shock-absorbing elements, containing the sifting body with two rows of sieves pairs. |

| 2. | Self adjusting grain feed. |

| 3. | Self cleaning of the sieve covers by means of rubber balls, Transparent plexiglass panels for checking the cereal strata. |

| 4. | Steel or wooden made sieve frames equipped with easily replaceable perforated plates. |

| 5. | The vibrator motors, which provides the oscillation for the separator. |

| 6. | To top it all the best quality vibrating motors are equipped which provides the oscillation for the Aspirator Separator. |

Vibrating process is maintained by means of vibro-motors, which are placed in the center of gravity of the machine. The grain feeding chamber and body which are mounted on the rubber shock absorbers by vibrating together and driven by vibro-motors convey the product into mid-section of inlet. The grain is separated uniformly on the entire surface of the screen by means of an adjustable regulating gate. If it is necessary, for better product flow another adjustable regulating gate can be fixed to the inlet of thescreen. When the grain passes through from the first screen to the second one, larger size impurities or foreign particles are kept by the first screen and directed to coarse offal discharge line. The remained smaller size impurities or foreign particles, which pass through the second screen, are transferred to fine offal discharge line. Then, the cleaned product is transported to an air canal or tarar.

S.NoContent

| 1. | Low energy consumption, high capacity and operating efficiency. |

| 2. | Easy and minimum maintenance, hassle free operation by using vibro-motors. |

| 3. | Adjustable inclination (angle) of mesh - grades range 2 - 12. Due to this unique feature, the Aspirator Separator can be used for any kind of cereals at maximum efficiency. |

| 4. | Durability and long lifetime. |

| 5. | Quick and easy replacement of mesh and practical cleaning possible. |

| 6. | Noiseless working. |

Mukul Enterprises: The Leading Vibro Separator Machine Manufacturer in India

Mukul Enterprises, based in Uttar Pradesh, India, was established in 1975, and today, it is one of the leading manufacturers of vibro separator machines that clean and separate grains and other commodities. In the past five decades, we have generated a strong reputation for our organisation as a one-stop shop for establishing flour mills in India and abroad.

Vibro separators are crucial equipment that helps in the removal of impurities in grain mills and grain storage facilities. The range of vibro separators offers high vibration techniques for gentle and efficient separation of coarse and fine impurities along with low densities like wheat, rice, corn, soybeans, pulses, spices, etc.

Mukul Enterprises is the oldest vibro separator machine manufacturer in India and has been involved in research and development in this area from the very beginning. The R&D centre is equipped with the most advanced technology and techniques and is manned by qualified personnel who keep on testing to improve the efficiency and sturdiness of the vibro separators. Over the years, we have made several changes regarding the design of the machines through the adoption of advanced technologies, which in turn have enhanced their performance and productivity.

Based in a large, state-of-the- art facility consisting of 10,000 sq. ft., our manufacturing unit is replete with state-of-the-art machinery and is staffed by more than 150 experienced operators. This not only ensures that quality is kept at a high level but also allows us to produce thousands of vibro separators every month to cater to the growing global demand. During the production of these machines, every aspect is taken care of with precision, right from sourcing and acquiring the finest components to assembly and even final performance tests are conducted by qualified technicians before a machine is released for sale.

Apart from offering vibro separators as standalone equipment, Mukul Enterprises offers end-to-end solutions to clients for establishing grain milling plants both nationally and internationally. We have a fully staffed project team that is tasked with entering into a project management mode when it comes to the development of large flour mills around the world. This involves process conceptualisation, layout design, installation, commissioning and testing of machines, as well as technical support for customers. In line with the specific business plans and requirements, we apply our industry experience and technical knowledge to develop specialised, high capacity projects that fit the client’s infrastructure solution.